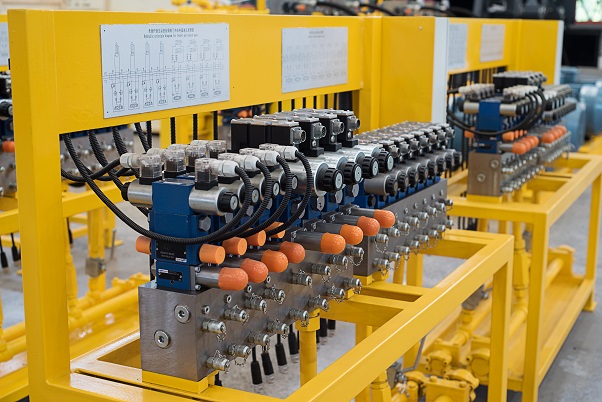

The Martin SITY2000 waste incinerator, originating from Germany, is recognized as the most widely used waste incinerator technology worldwide. This waste incinerator system consists of a feeding system, an incineration system, a slag removal system, a hydraulic system, a combustion air system, and a combustion control system. The incinerator's treatment capacity can range from 50 tons to 1200 tons per day.

The incinerator final assembly base, completed in 2008, serves as the industrialization base for the National Environmental Protection Waste Incineration and Recycling Engineering Technology Center. It is recognized as the world's largest incinerator final assembly base. The incinerator final assembly base is primarily focused on the design, manufacturing, final assembly, commissioning, and supply of waste incinerators. The incinerator production and assembly process is carried out by four automated workstations (robots) for intelligent manufacturing. We have successfully developed a range of standardized and serialized incinerator products that are also suitable for improving fluidized bed incinerators.

As of February 2023, our incinerator products have been applied to a total of 393 waste incineration lines within 239 waste incineration projects worldwide. Our technical equipment sales have reached Macao SAR and eight countries, including Germany, the United States, India, Vietnam, Thailand, Brazil, Sri Lanka, and Ethiopia.

Technical characteristics of SITY2000 mechanical grate incinerator:

Typical reverse-acting mechanical grate;

24° inclination angle between the grate and the horizontal plane;

Upper and lower grate sections that can be adjusted independently, allowing for precise control of the combustion;

Evenly distributed primary air, ensuring complete waste combustion and resulting in a low loss on ignition of slag (≤3%);

Rational secondary air injection inlet, ensuring complete combustion of combustible gases;

Modular grate design, facilitating its incorporation into various incinerator products with different treatment capacities and good interchangeability. Can be designed with options such as an adiabatic furnace, semi-water-cooled furnace, or full water-cooled furnace, depending on the calorific value of the municipal solid waste;

Suitable for treating municipal solid waste with varying calorific values, and also treating waste similar to municipal solid waste or mixed with sludge, biomass, or other similar waste.

- Home

- About Us

Company Profile | History | Organization | Global Performance Overview

- Core Advantages

Core technology | Engineering Center | Standards Compilation | Technology Research&Development | Patent and Innovation

- Business Overview

Waste-to-Energy EPC service | Core Products | Operation&Maintenance Service | Boiler surfacing

- News&Information

- Human Resources

Core Products

Core Products